FORGING PROCESSES Metal Forging Drop Forging Hammers Hydraulic And Mechanical Presses Heading Or Upset Forging Metal Piercing Metal Sizing Roll Forging Swaging Or Radial Forging Metal Hobbing Metal Ball Forging Orbital Forging Riveting Metal Coining Isothermal Forging Trimming Of Forged Parts High Energy Rate Forging MANUFACTURING PROCESSES Metal Casting Metal Forming Metal Rolling Metal Extrusion Metal Drawing Sheet Metal Powder Processes

Ring Forging

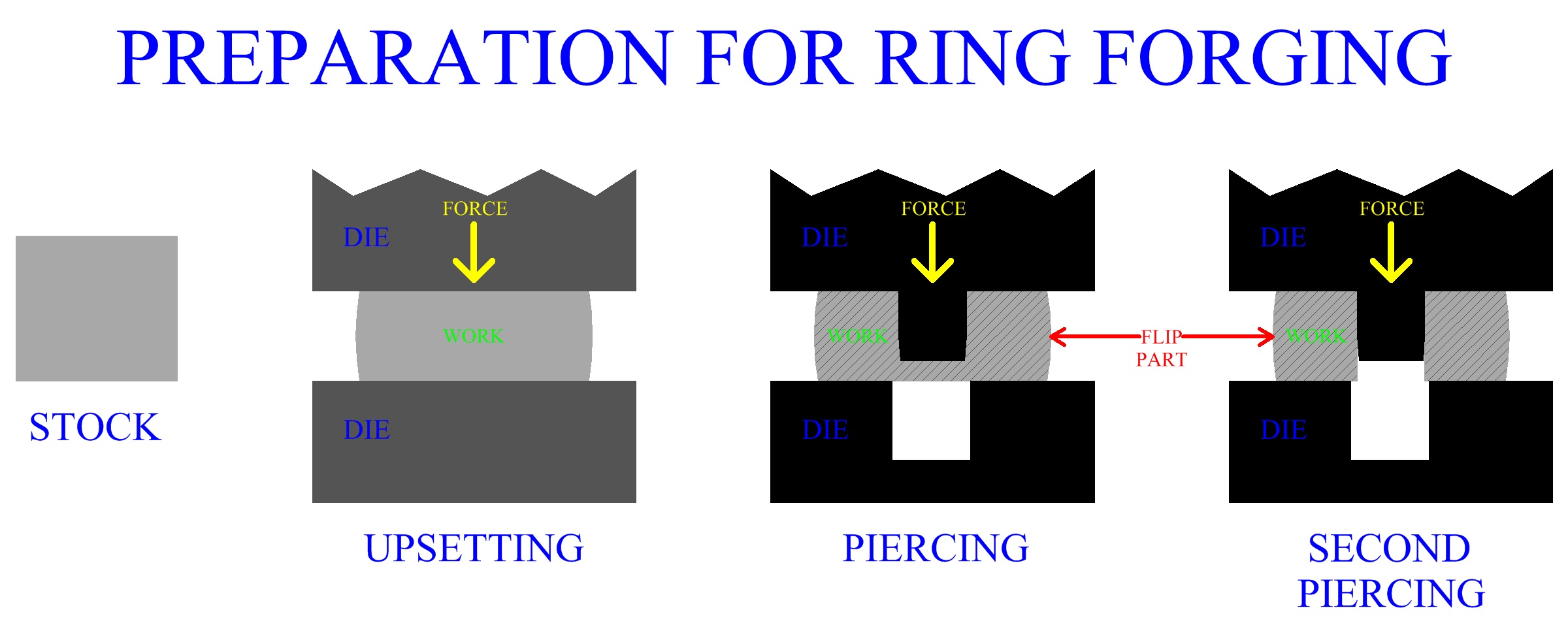

Seamless metal rings, of different sizes, are commonly manufactured in modern industry for various applications, such as parts for machine tools, aerospace applications, turbines, pipes and pressure vessels. Production of rings by rolling was discussed earlier in ring rolling. Ring forging is a different manufacturing process than ring rolling but the two have similarities. One important similarity is that they are both metal forming operations and will affect the mechanical properties of the ring's material. In the first stage of ring forging, a stock is cut to length, upset, then pierced all the way through to create a hole in the center.

Figure:201

|

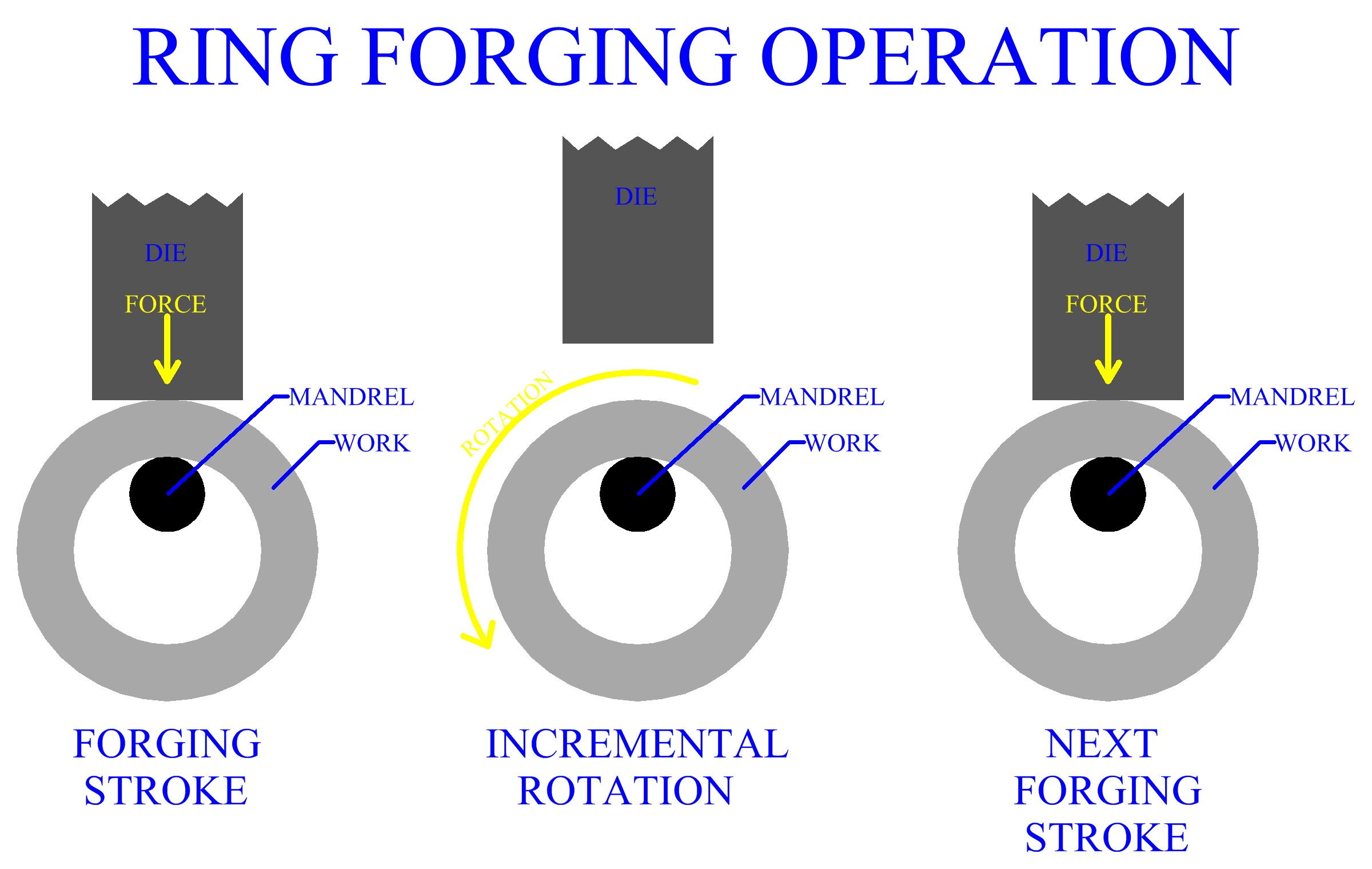

Once the work piece is pierced all the way through, it is ready to be ring forged. The work is placed on a mandrel or saddle. The ring is then formed by the up and down motion of a forging die that hammers the material from above, as the work is incrementally rotated in a series of steps that will forge the ring to its final size.

Figure:202

|