FORGING PROCESSES Metal Forging Drop Forging Hammers Hydraulic And Mechanical Presses Heading Or Upset Forging Metal Piercing Metal Sizing Roll Forging Swaging Or Radial Forging Metal Ball Forging Orbital Forging Ring Forging Riveting Metal Coining Isothermal Forging Trimming Of Forged Parts High Energy Rate Forging MANUFACTURING PROCESSES Metal Casting Metal Forming Metal Rolling Metal Extrusion Metal Drawing Sheet Metal Powder Processes

Metal Hobbing

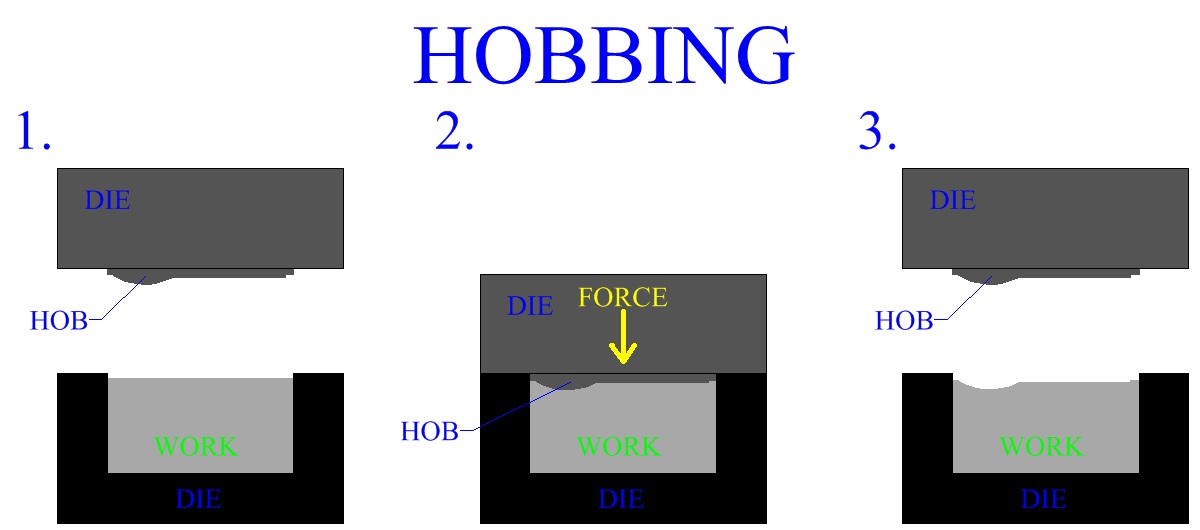

Hobbing is a cold working, metal forging process in which a punch, with an exact geometry at its end, is pressed into a work piece. The special punch, called a hob, will create a cavity with the precise dimensions desired. Due to the high tolerances of the hob, the high pressures applied during the manufacturing process, and the fact that the operation is performed cold, very accurate dimensions and surface quality are obtained within the cavity. The hob is most often machined from hardened steel. The following illustrates a hobbing operation used to manufacture a cavity for an impression die.

Figure:197

|

A common application of hobbing in modern industry is to produce molds or die cavities for other manufacturing processes such as plastic molding, die casting, and other metal forging processes. It may be possible to machine the cavity into the work piece. However, in situations where a hob is used, it is often easier to machine the outer dimensions onto the hob than the inner dimensions onto the work piece. Also, once the hob is manufactured, it is easy to produce many identical cavities with the same hob. Pressing the hob into the metal is easier than machining the work. Since hobbing is performed cold, strain hardening of the metal could be a factor. Sometimes the work may be annealed to recover the material.