FORGING PROCESSES Metal Forging Drop Forging Hammers Hydraulic And Mechanical Presses Heading Or Upset Forging Metal Piercing Metal Sizing Roll Forging Swaging Or Radial Forging Metal Hobbing Metal Ball Forging Orbital Forging Ring Forging Riveting Isothermal Forging Trimming Of Forged Parts High Energy Rate Forging MANUFACTURING PROCESSES Metal Casting Metal Forming Metal Rolling Metal Extrusion Metal Drawing Sheet Metal Powder Processes

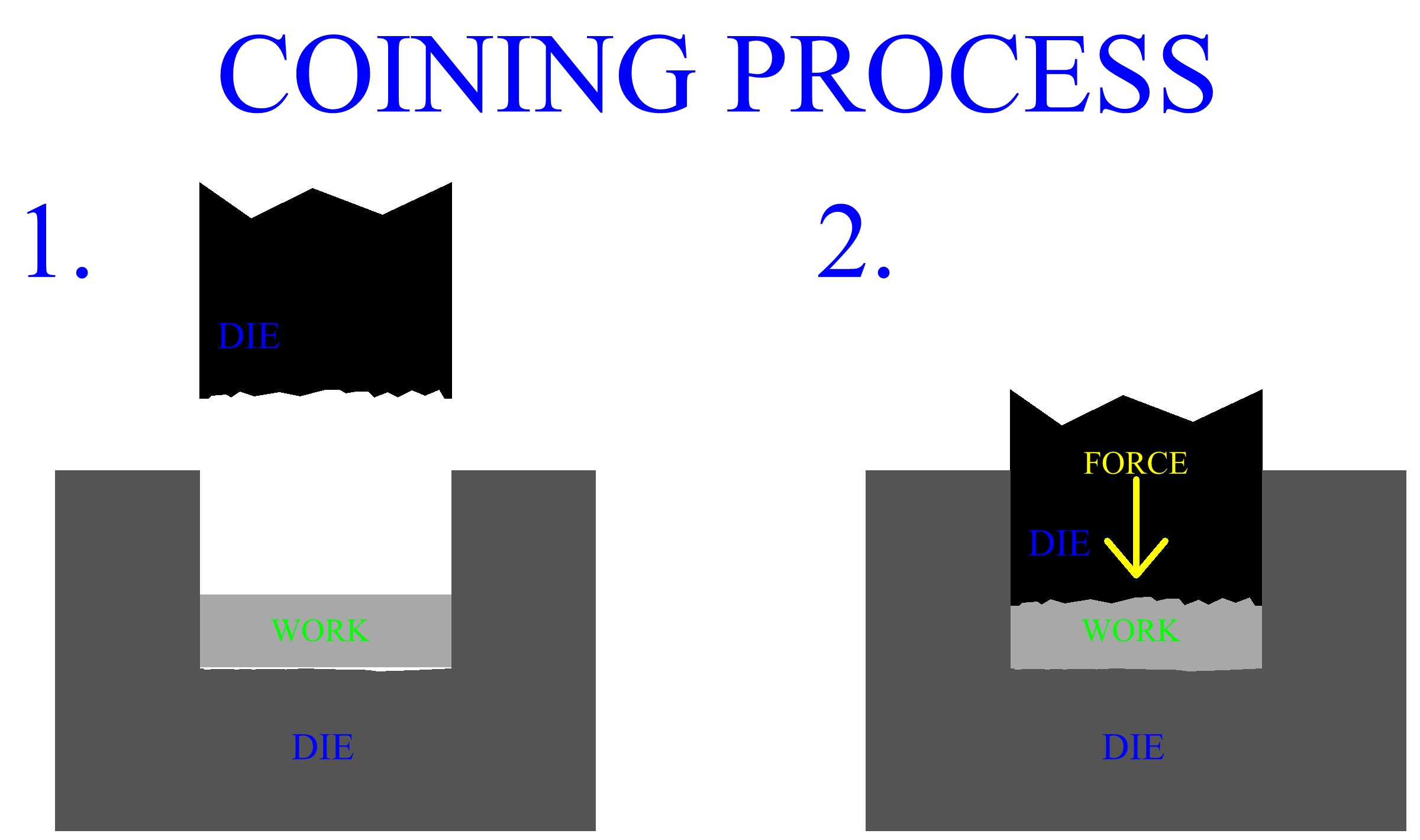

Metal Coining

Metal coining is a forging process by which very fine and intricate details can be created on the surface of a work piece. Coining may be used to control surface quality and detail on parts. Metal coining is often a finishing process for manufactured products. This is a flashless, precision forging operation, that due to the required accuracy of the process, is performed cold. Lubrication is not used, since any substance between the die and work would hinder the reproduction of the most accurate details that are to be formed on the work's surface. In the coining process, a large amount of force is exerted on the forging, over a short distance. Mechanical presses are often used for these operations.

Figure:204

|