| Manufacturing Home

METAL ROLLING

PROCESSES

Metal Rolling

Shape Rolling

Thread Rolling

Rotary Tube Piercing

MANUFACTURING

PROCESSES

Metal Casting

Metal Forming

Metal Forging

Metal Extrusion

Metal Drawing

Sheet Metal

Powder Processes

|

Ring Rolling

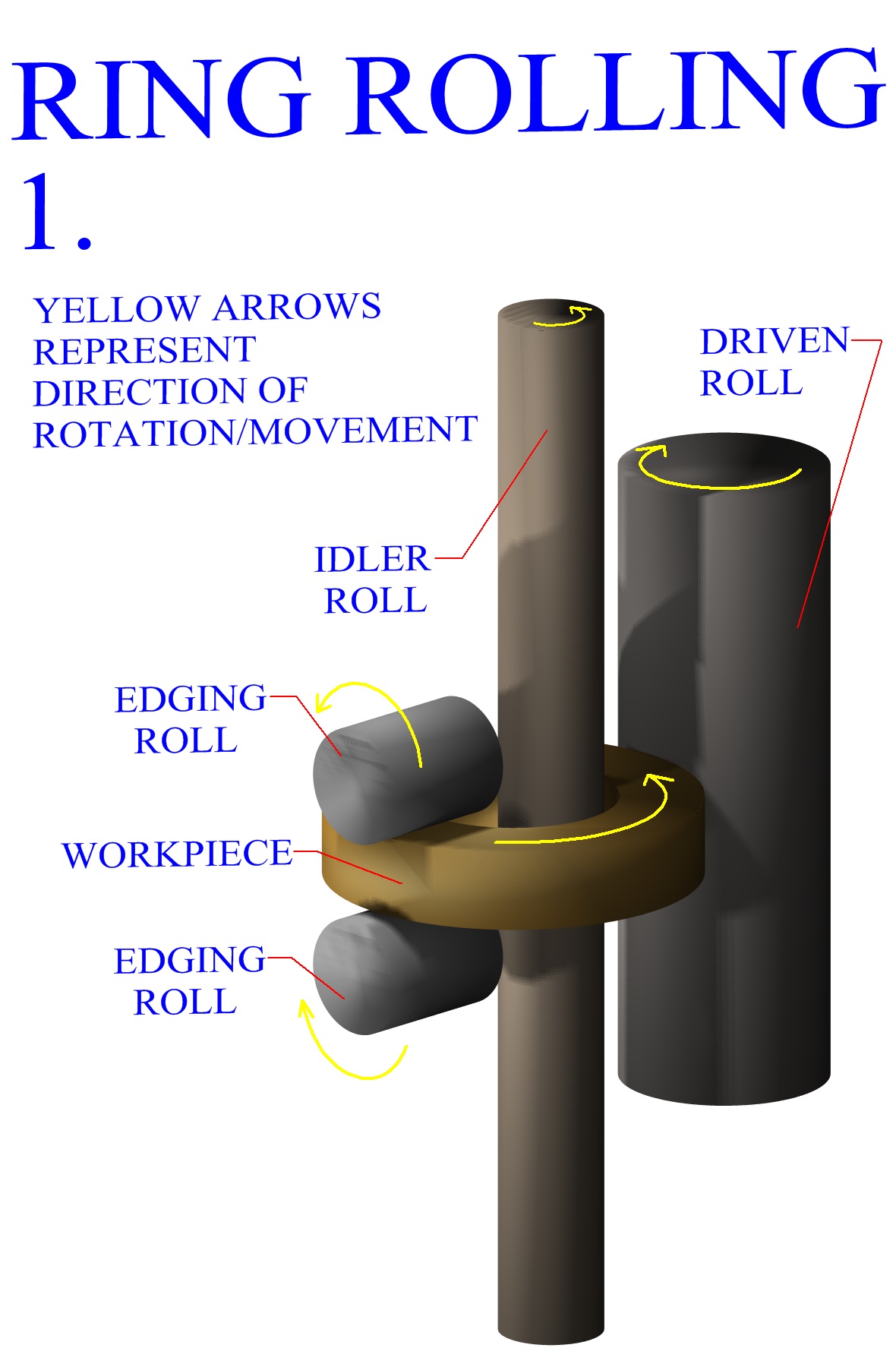

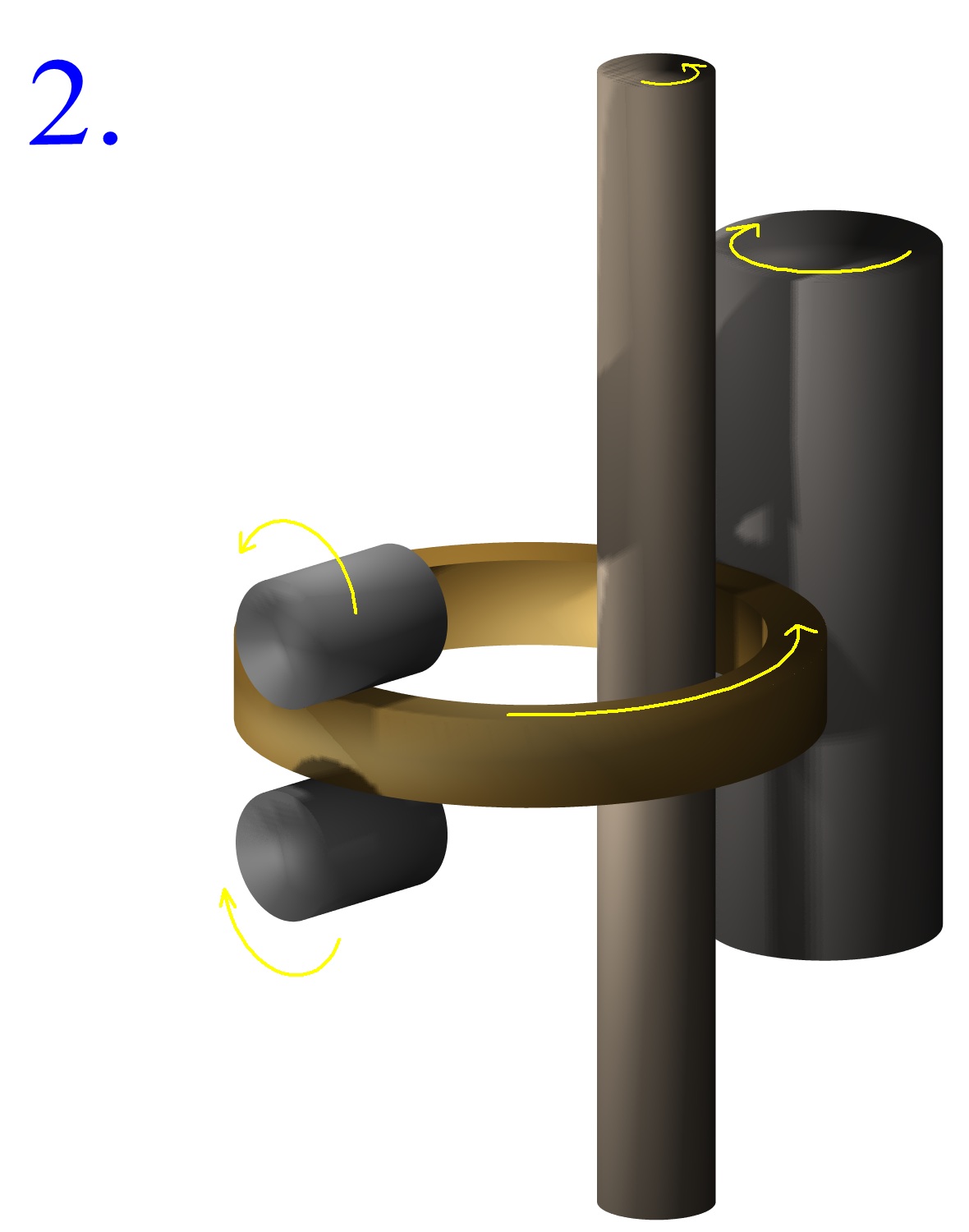

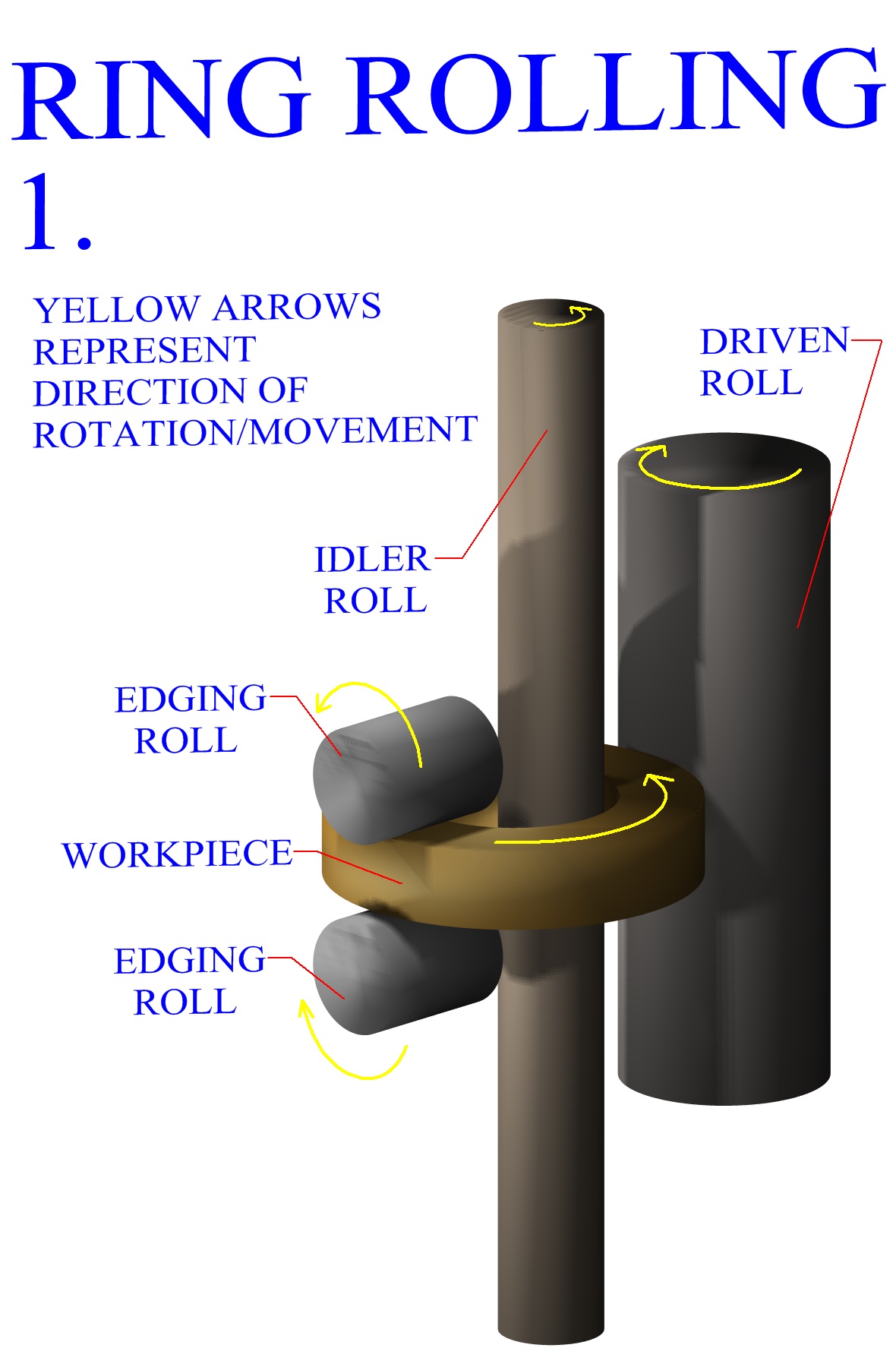

Ring rolling is a particular category of metal rolling, in which a ring of smaller

diameter is rolled into a precise ring of larger diameter and a reduced cross

section. This is accomplished by the use of two rollers, one driven and one idle,

acting on either side of the ring's cross section. Edging rollers are typically used

during industrial metal rolling manufacture, to ensure that the part will maintain a

constant width throughout the forming operation. The work will

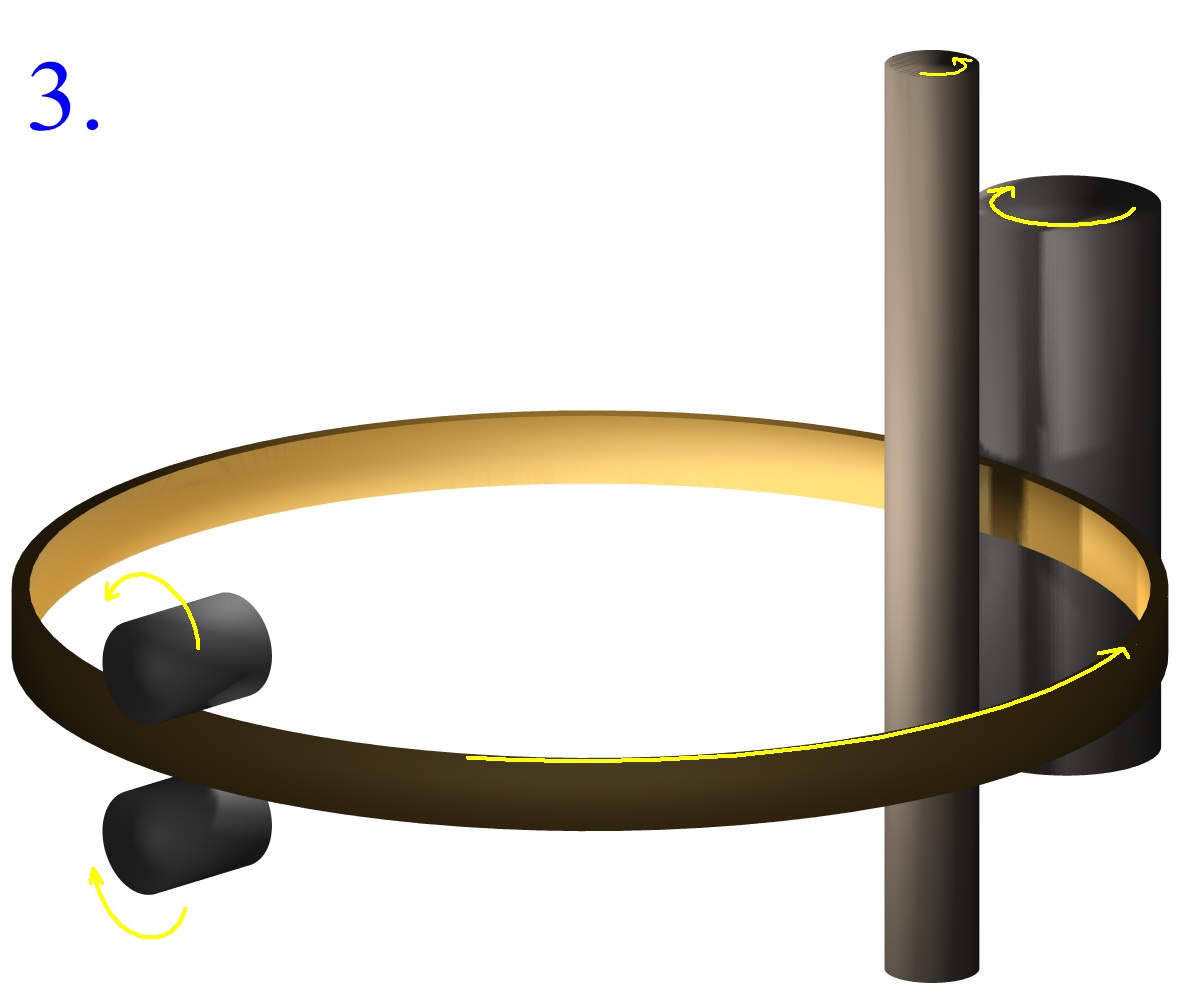

essentially retain the same volume, therefore the geometric reduction in thickness

will be compensated for entirely by an increase in the ring's diameter.

Rings manufactured by ring rolling are seamless. This forming

process can be used to manufacture not

only flat rings, but rings of differently shaped cross sections as well, producing very

precise parts with little waste of material.

A significant advantage of parts produced

by this metal rolling process is that the forming of the material will impart the ring

with a grain orientation that gives it enhanced strength relative to most applications.

Common items produced by this process in manufacturing industry today include

rings for machinery, aerospace applications, turbines, pipes, pressure vessels, roller and ball bearing

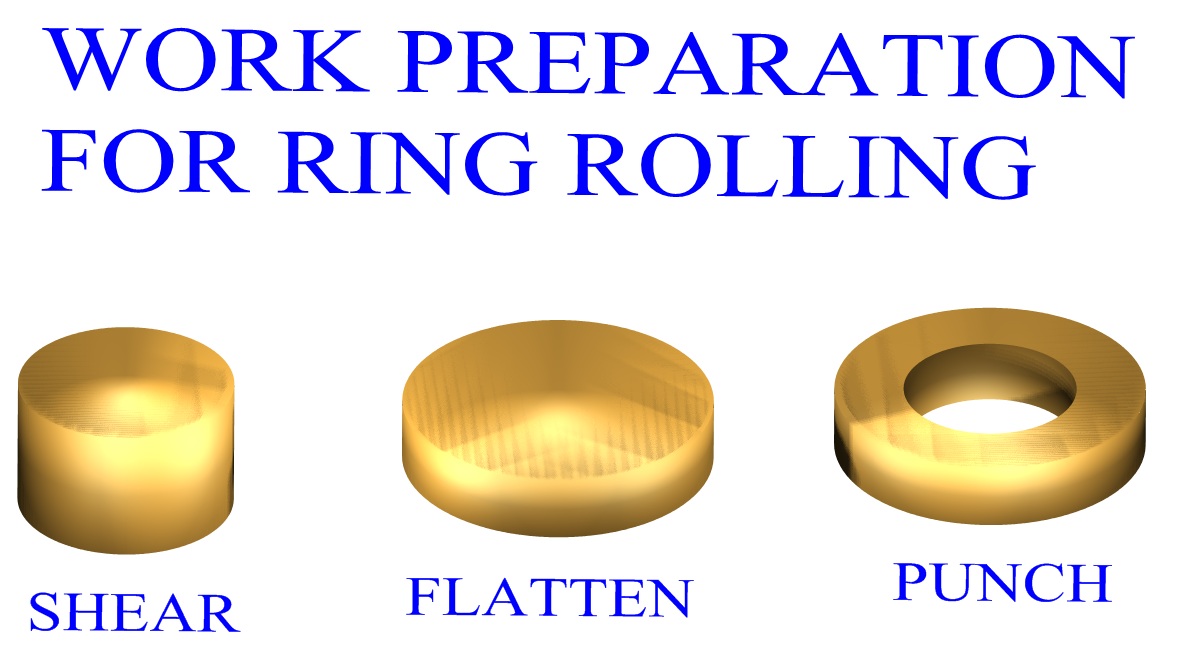

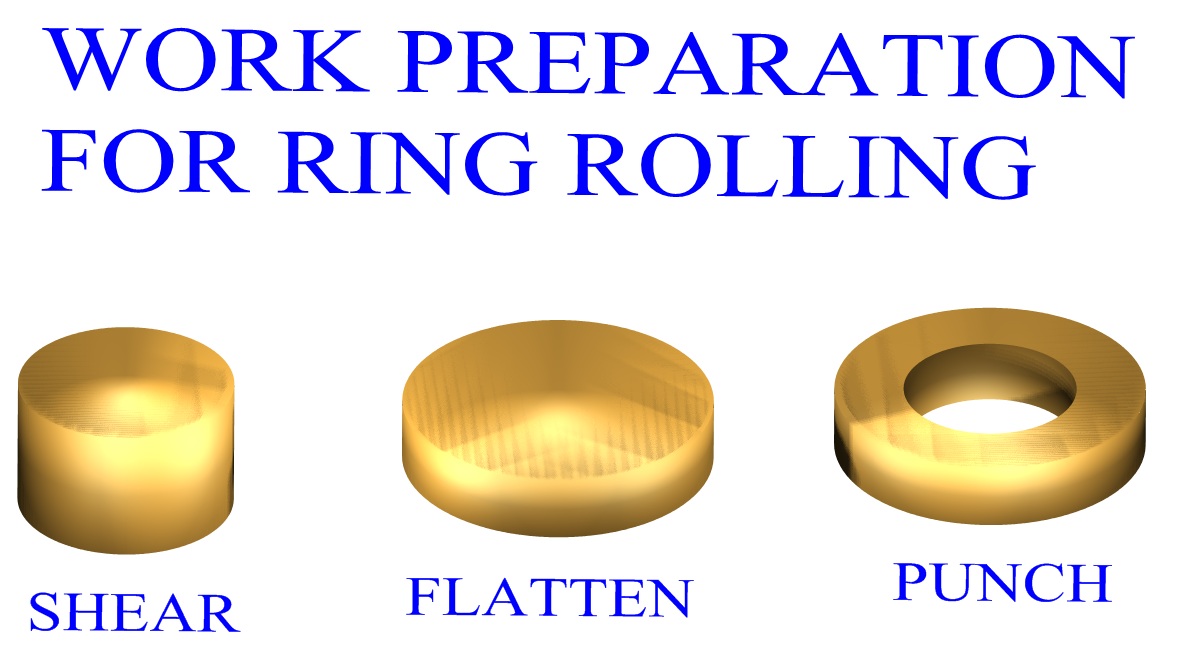

races. The following shows the sequence of events of the ring rolling process, the part is

commonly started as a metal bar cut to a certain length.

Figure:149

|

Figure:150

|

|

PRIVACY POLICY

|