FORGING PROCESSES Metal Forging Drop Forging Hammers Hydraulic And Mechanical Presses Heading Or Upset Forging Metal Piercing Metal Sizing Roll Forging Swaging Or Radial Forging Metal Hobbing Metal Ball Forging Orbital Forging Ring Forging Riveting Metal Coining Isothermal Forging Trimming Of Forged Parts MANUFACTURING PROCESSES Metal Casting Metal Forming Metal Rolling Metal Extrusion Metal Drawing Sheet Metal Powder Processes

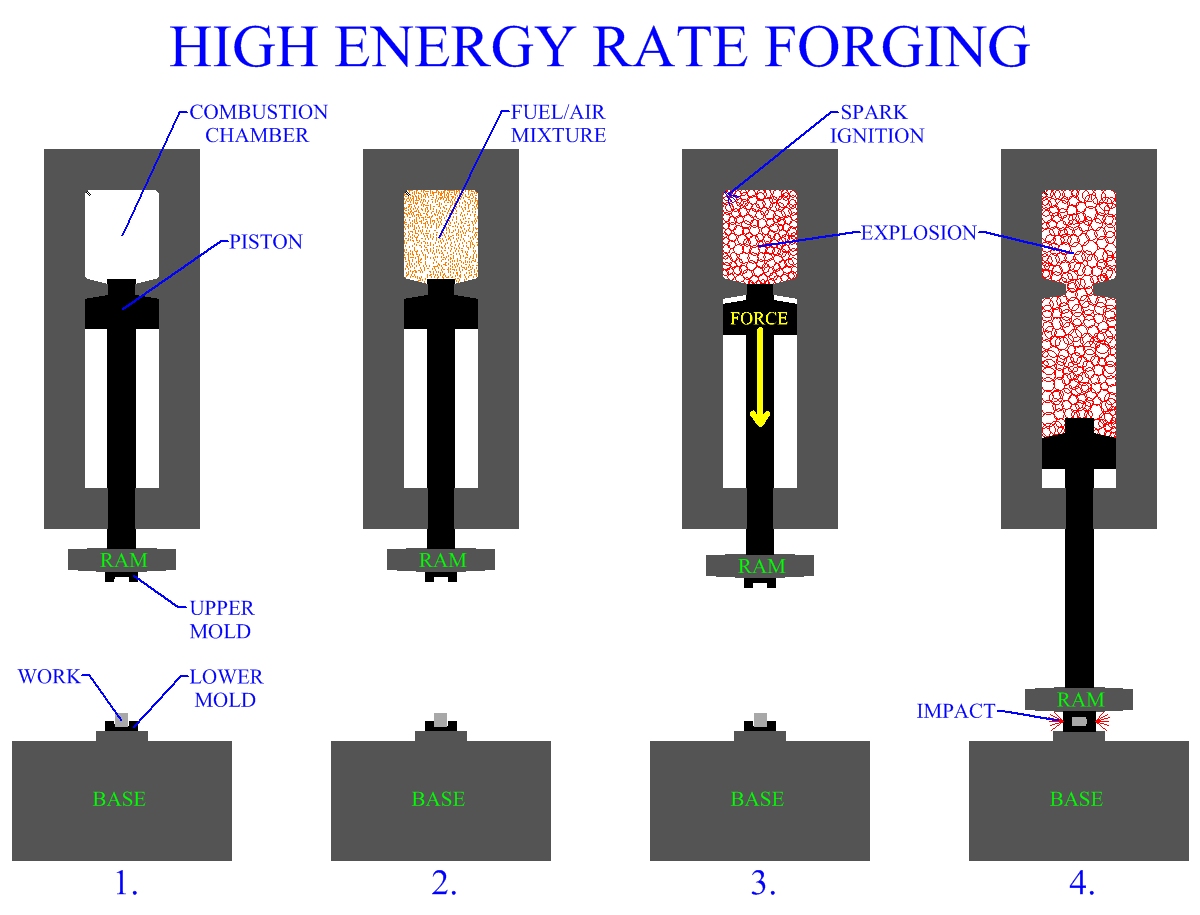

High Energy Rate Forging

High energy rate forging, is a metal forging process in which the actual forging of the work occurs in a few thousandths of a second. This type of manufacturing technique is very useful for hard to forge metals. As discussed in isothermal forging, there may be reasons that the cooling of a part during the process may create problems. Such as, mechanical properties of some metals can vary considerably over a short temperature range, some metals are difficult to form at lower temperatures, or parts may have thin, complex sections. Isothermal forging was developed specifically to deal with the problems associated with cooling of the metal at the work-die interface. High energy rate forging also solves that same problem, but by a different method. Since the part is forged so fast, there is no time for cooling to occur during the forging of the work. With high energy rate forging, hard to forge materials, and thin, complicated parts can be forged with a single stroke.

A petro forge is a machine designed to perform high energy rate forging operations. The petro forge bears some similarities to the engine in a car, in that it does employ an internal combustion chamber for its working energy. The upper die of the mold is attached to the ram, that is a part of a piston that is located under a combustion chamber. Basically, the combustion chamber is filled with a fuel-air mixture. The mixture is then ignited by a spark plug, creating an explosion in the chamber. This explosion forces the piston, ram, and upper die downward with tremendous power. The upper apparatus accelerates towards the work, striking it with a great velocity, forging the part in a few milliseconds. Back pressure is then used to raise the apparatus, returning it to its position, this also occurs rapidly. During industrial manufacture, forging die can strike the work at velocities of 750 feet per second. The power and velocity employed during this process raises many concerns with regard to safety.

Figure:207

|