METAL ROLLING PROCESSES Metal Rolling Shape Rolling Ring Rolling Rotary Tube Piercing MANUFACTURING PROCESSES Metal Casting Metal Forming Metal Forging Metal Extrusion Metal Drawing Sheet Metal Powder Processes

Thread Rolling

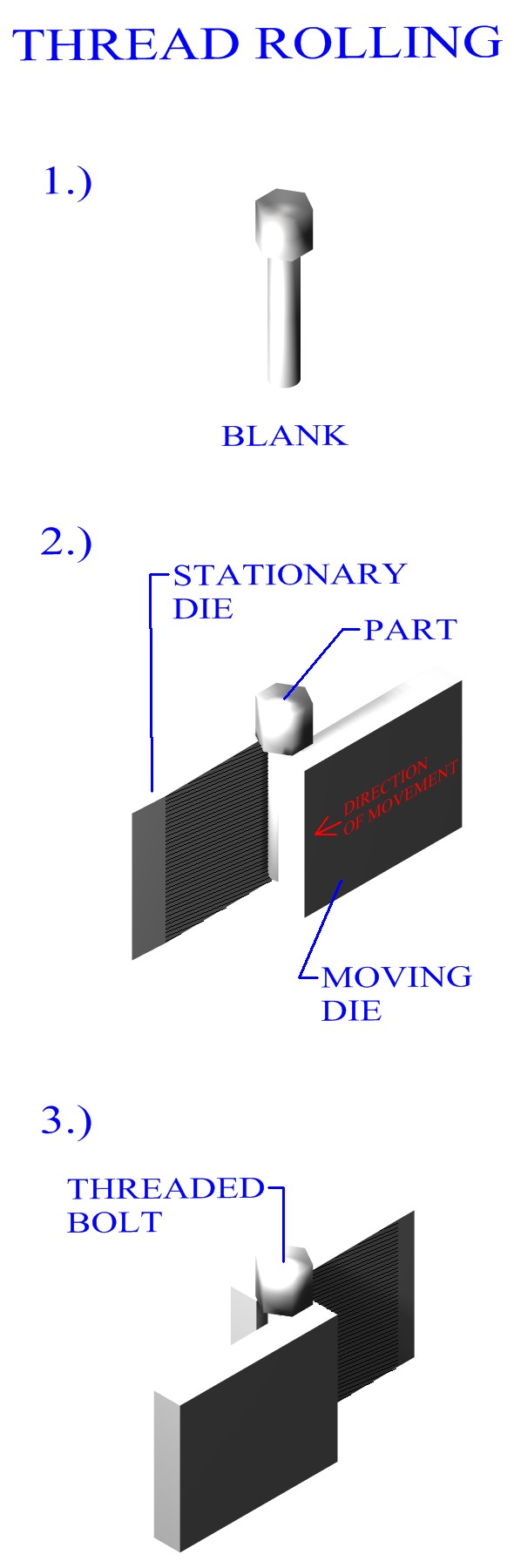

Thread rolling is a metal rolling process used extensively in manufacturing industry to produce screws, bolts and other fasteners. A common thread rolling process, used in industry to manufacture threaded parts, involves forming the threads into the metal of a blank by a pressing and rolling action between two die. The die surfaces hold the shape and the force of the action forms the threads into the material. A similar metal forming process has been developed for the production of gears.

Thread rolling, in modern manufacturing, has an extremely high productivity rate, significantly higher than producing threaded parts by machining. Machining is the alternative method to industrial manufacturing of threaded parts. Producing threads by this method has several other benefits over machining. Forming will harden the metal through cold working, does not waste material by cutting, and produces a favorable grain structure to strengthen the part with respect to its function.

Figure:151

|