METAL ROLLING PROCESSES Metal Rolling Ring Rolling Thread Rolling Rotary Tube Piercing MANUFACTURING PROCESSES Metal Casting Metal Forming Metal Forging Metal Extrusion Metal Drawing Sheet Metal Powder Processes

Shape Rolling

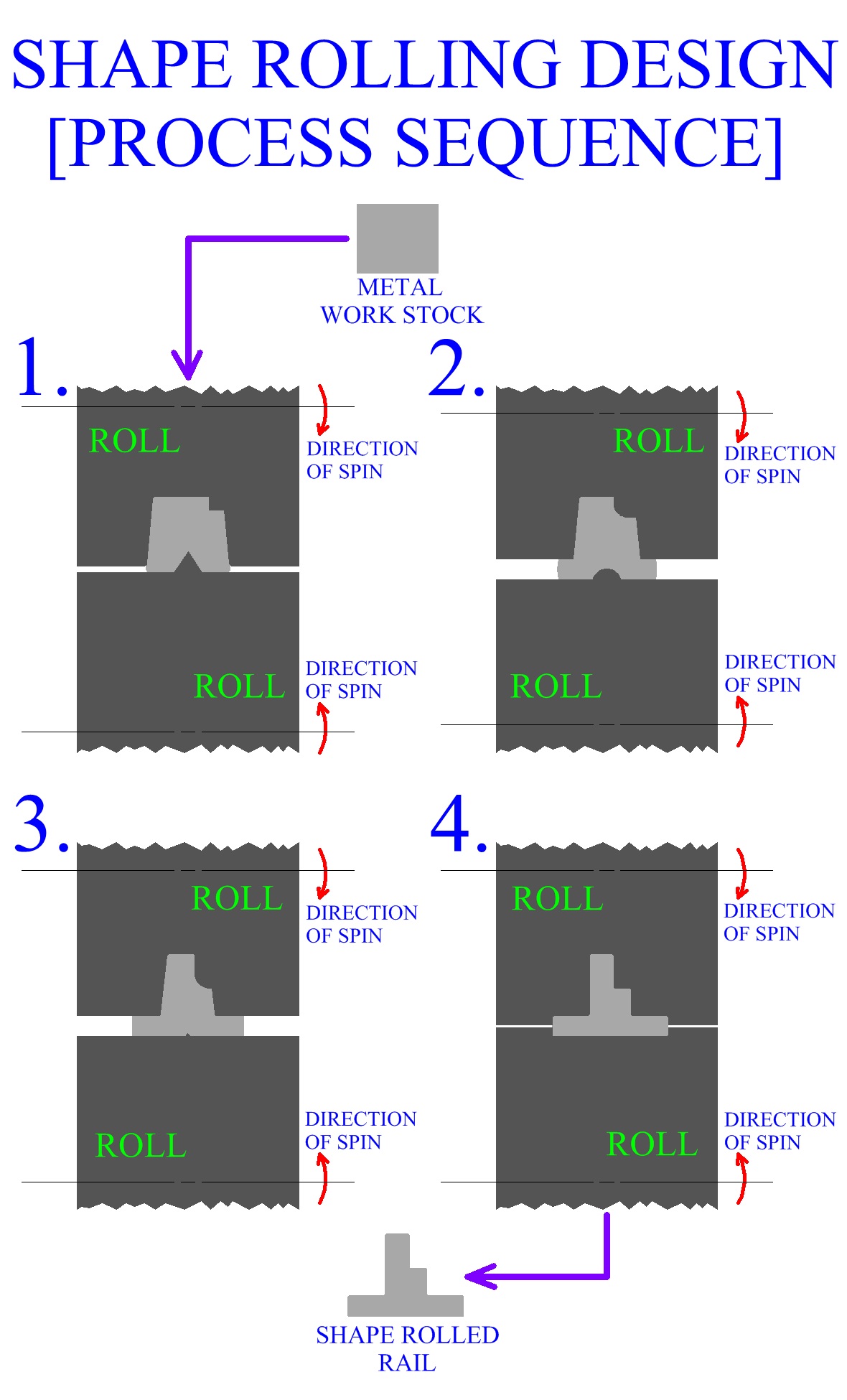

Shape rolling is a broad term for a range of metal rolling operations, that involve forming the work with rolls of a certain geometry. The rolls form the part to a specific shape. Most shape rolling involves passing the material through several steps. Two very common examples of continuous shape rolled product are the I beam for structural purposes and the rail for railroad track.

Designing a proper series of shape changes in a work will involve more deformation in some areas than others. As mentioned earlier, excessive shape change in some parts of the cross section is a serious cause of defects in shape rolling production. The rolling engineer must design a system of passes in such a way as to achieve the shape change through several steps, mitigating any excessive deformations at any particular area of the work's cross section.

Many different shapes can be shape rolled in metal rolling industry today. Here is an example of a possible roll pass design for the production of a rail for a machine.

Figure:148

|