METAL CASTING PROCESSES Metal Casting Principles Metal Casting Metal Casting Operation Effect Of Gases On Metal Casting Metal Casting Design Expendable Mold Casting Sand Casting Plaster Mold Casting Ceramic Mold Casting Shell Mold Casting Vacuum Casting or V-process Expanded Polystyrene Casting Investment Casting Permanent Mold Casting Basic Permanent Mold Casting Slush Casting Pressure Casting Die Casting Hot Die Casting Cold Die Casting True Centrifugal Casting Semicentrifugal Casting Centrifuge Casting Ingot Casting Continuous Casting MANUFACTURING PROCESSES Metal Forming Metal Rolling Metal Forging Metal Extrusion Metal Drawing Sheet Metal Powder Processes

Vacuum Permanent Mold Casting

Vacuum permanent mold casting is a permanent mold casting process employed in manufacturing industry that uses the force caused by an applied vacuum pressure to draw molten metal into and through the mold's gating system and casting cavity. This process has a similar name to vacuum mold casting discussed in the expendable mold process section; however these are two completely different manufacturing processes and should not be confused with each other.

The Process

A permanent mold containing the part geometry and the gating system is created, (usually accurately machined), similar to the molds employed in the other permanent mold processes. The mold in vacuum mold casting is much like the mold in the pressure casting manufacturing process, in that the gating system is designed so that the flow of molten material starts at the bottom and flows upwards.

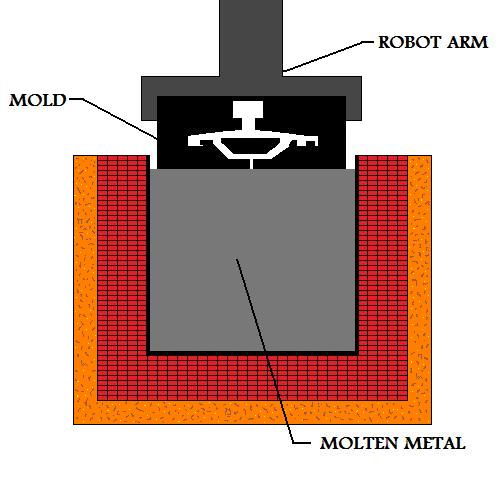

Figure:78

|

The mold is suspended over a supply of liquid metal for the casting by some mechanical device, possibly a robot arm.

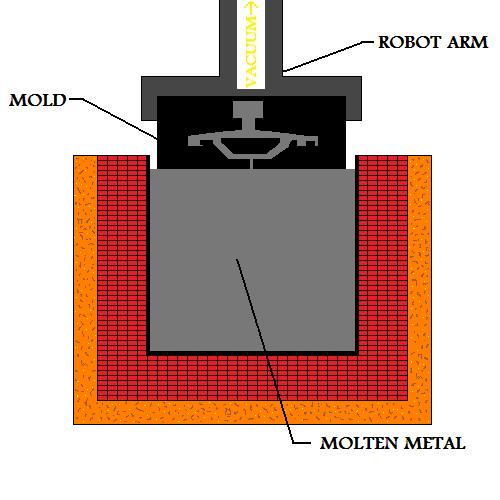

Figure:79

|

A vacuum force is applied to the top of the mold. The reduced pressure within the mold causes molten metal to be drawn up through the gating system and casting cavity.

Figure:80

|

As the casting solidifies, the mold is withdrawn from its position over the molten metal and opened to release the casting.

Properties And Considerations Of Manufacturing By Vacuum Casting

- This manufacturing process can produce metal castings with close dimensional accuracy, good surface finish, and superior mechanical properties.

- Castings with thin walled sections may be manufactured using this technique.

- This process is very much like pressure casting in the way the mold is filled, but since vacuum force is used instead of air pressure, gas related defects are reduced.

- Set up cost make this manufacturing process more suitable to high volume production, instead of small batch manufacture.