METAL CASTING PROCESSES Metal Casting Principles Metal Casting Metal Casting Operation Effect Of Gases On Metal Casting Metal Casting Design Expendable Mold Casting Sand Casting Plaster Mold Casting Ceramic Mold Casting Shell Mold Casting Expanded Polystyrene Casting Investment Casting Permanent Mold Casting Basic Permanent Mold Casting Slush Casting Pressure Casting Vacuum Permanent Mold Casting Die Casting Hot Die Casting Cold Die Casting True Centrifugal Casting Semicentrifugal Casting Centrifuge Casting Ingot Casting Continuous Casting MANUFACTURING PROCESSES Metal Forming Metal Rolling Metal Forging Metal Extrusion Metal Drawing Sheet Metal Powder Processes

Vacuum Casting

Vacuum mold casting, also known in manufacturing industry as the V process, employs a sand mold that contains no moisture or binders. The internal cavity of the mold holds the shape of the casting due to forces exerted by the pressure of a vacuum. Vacuum molding is a casting process that was developed in Japan around 1970.

The Process

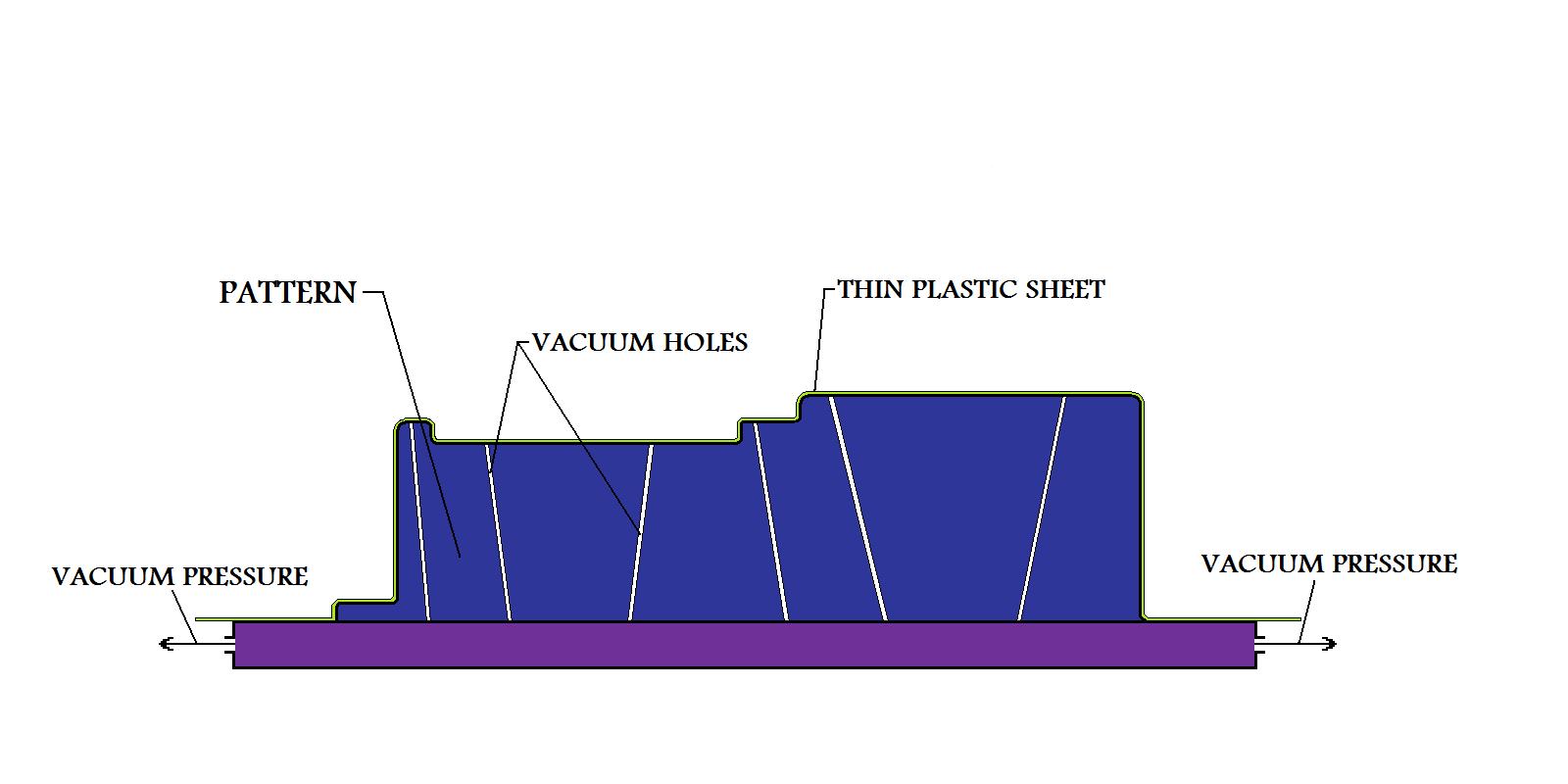

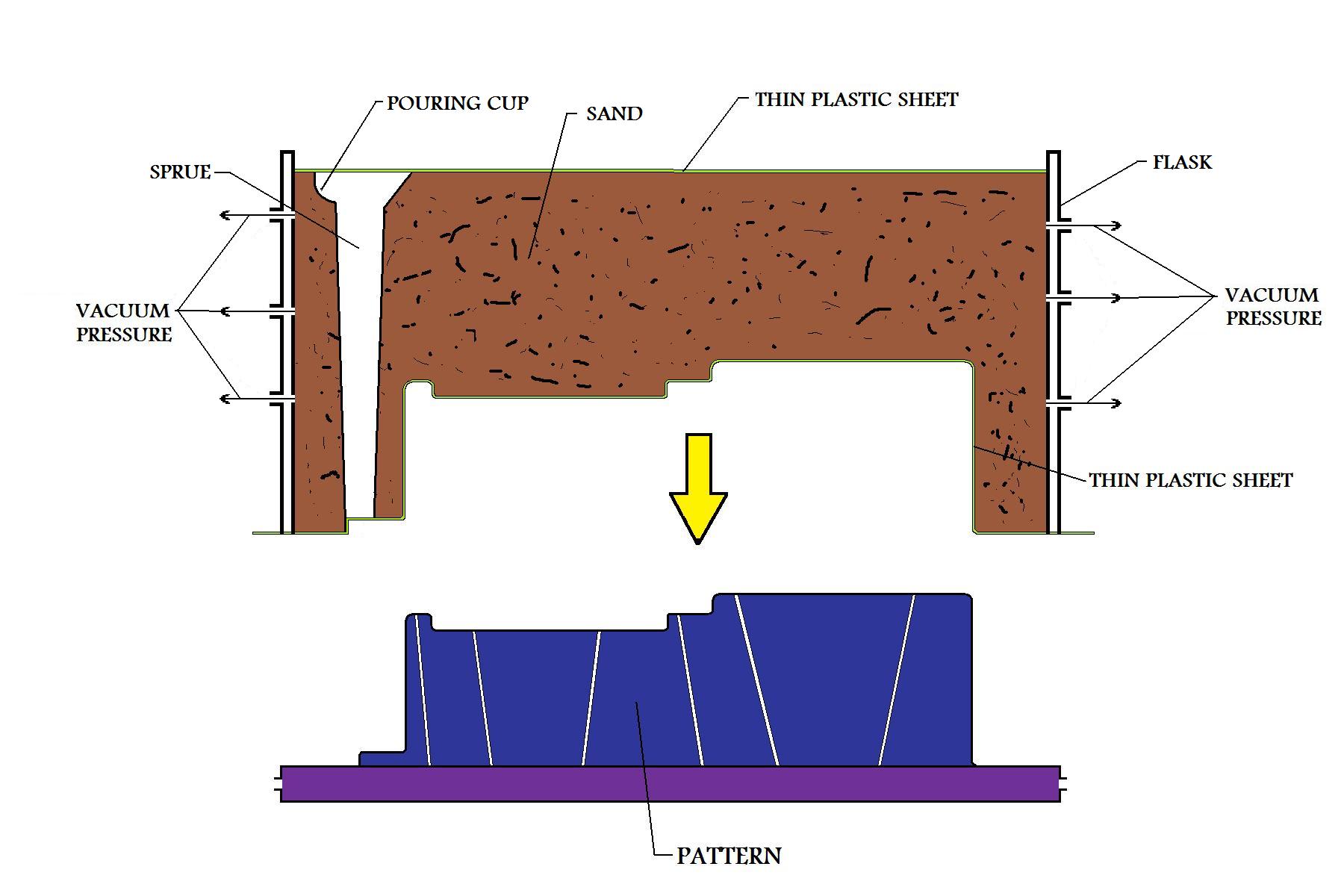

A special pattern is used for the vacuum mold casting process. It is either a match-plate or a cope and drag pattern with tiny holes to enable a vacuum suction. A thin plastic sheet is placed over the casting pattern and the vacuum pressure is turned on, causing the sheet to adhere to the surface of the pattern. Figure:37

|

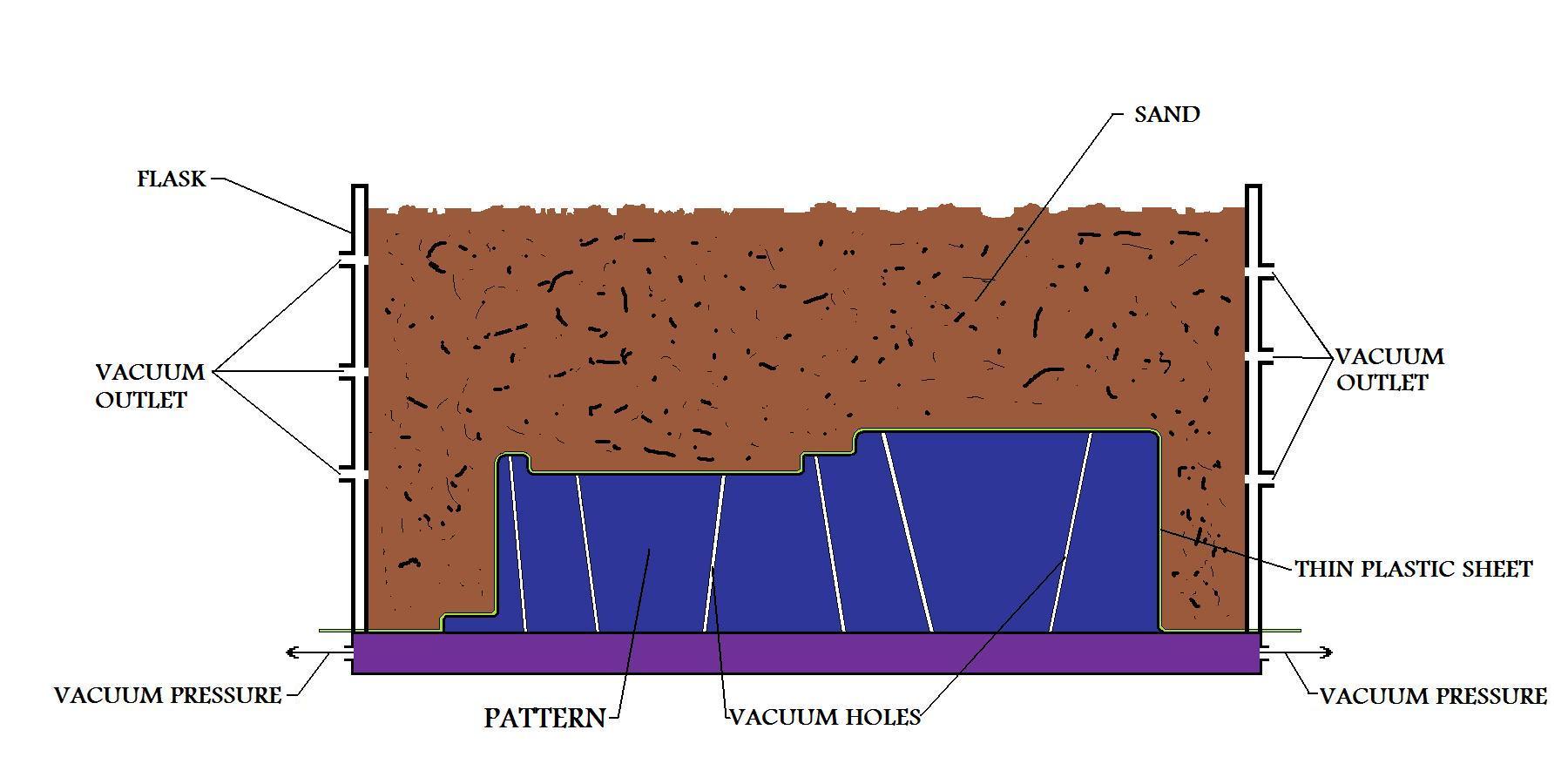

A special flask is used for this manufacturing process. The flask has holes to utilize vacuum pressure. This flask is placed over the casting pattern and filled with sand.

Figure:38

|

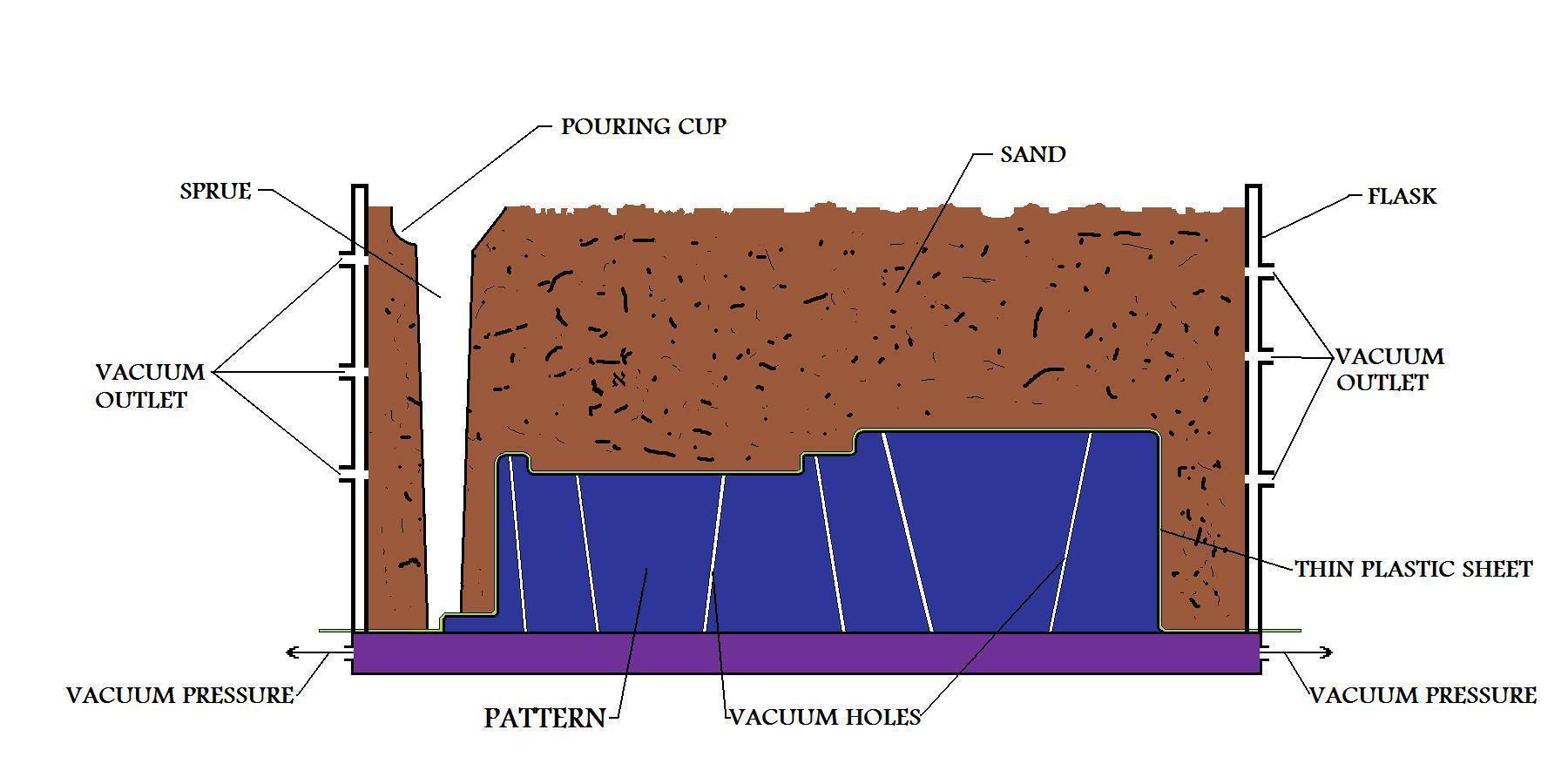

A pouring cup and sprue are cut into the mold for the pouring of the metal casting.

Figure:39

|

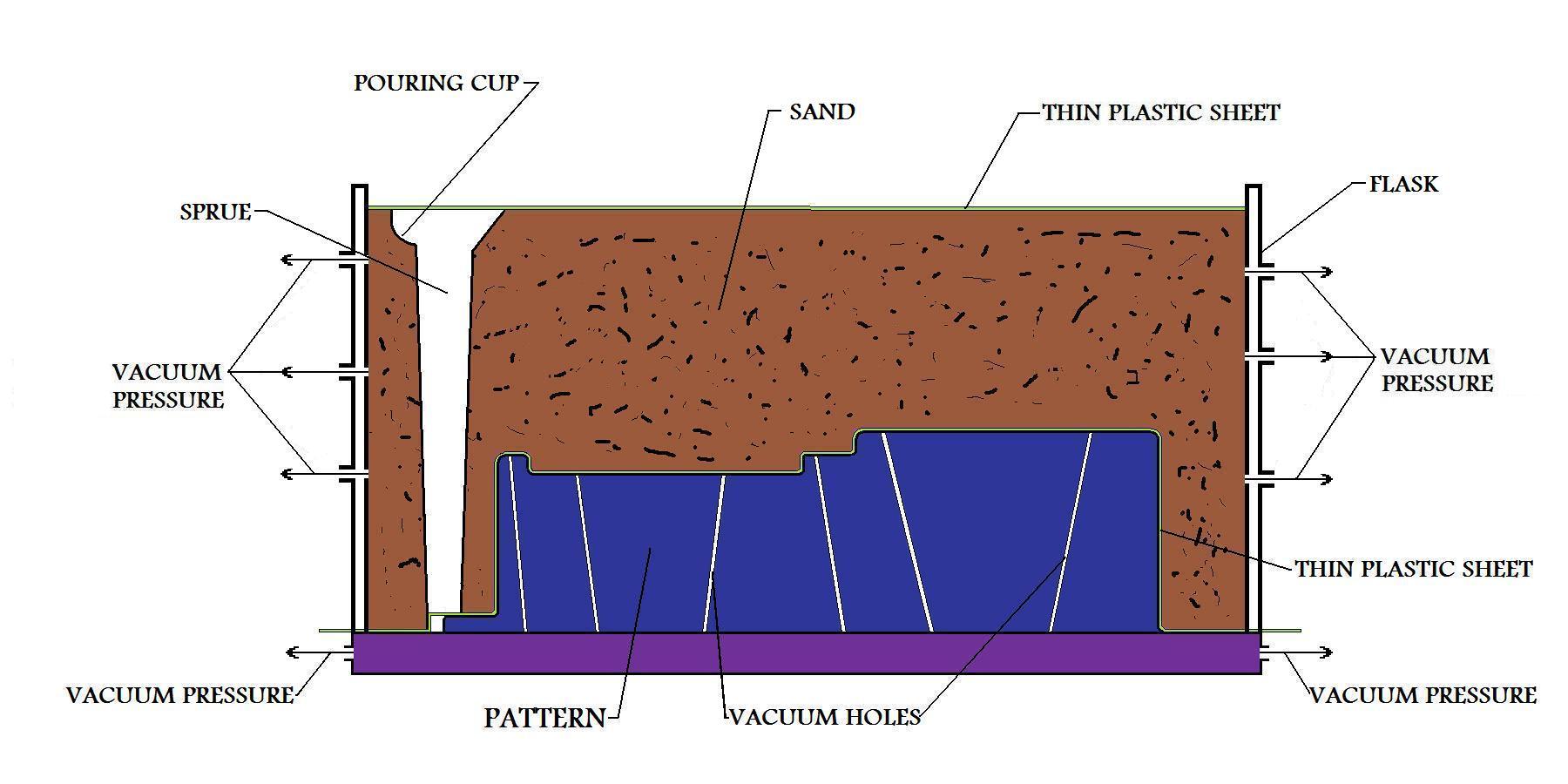

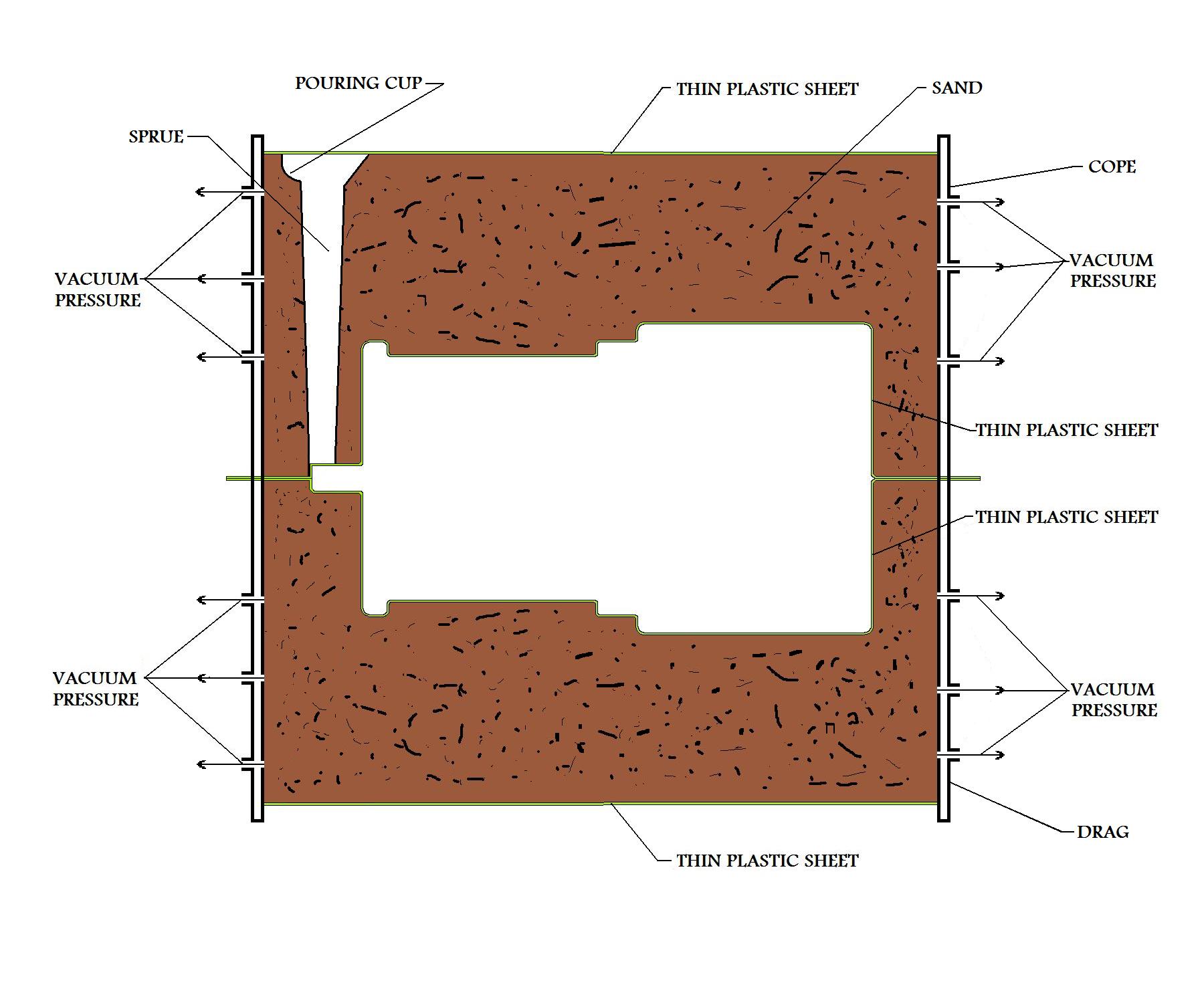

Next, another thin plastic sheet is placed over the top of the mold. The vacuum pressure acting through the flask is turned on, and the plastic film adheres to the top of the mold.

Figure:40

|

In the next stage of vacuum mold casting manufacture, the vacuum on the special casting pattern is turned off and the pattern is removed. The vacuum pressure from the flask is still on. This causes the plastic film on the top to adhere to the top and the plastic film formerly on the pattern to adhere to the bottom. The film on the bottom is now holding the impression of the casting in the sand with the force of the vacuum suction.

Figure:41

|

The drag portion of the mold is manufactured in the same fashion. The two halves are then assembled for the pouring of the casting. Note that there are now 4 plastic films in use. One on each half of the internal casting cavity and one on each of the outer surfaces of the cope and drag.

Figure:42

|

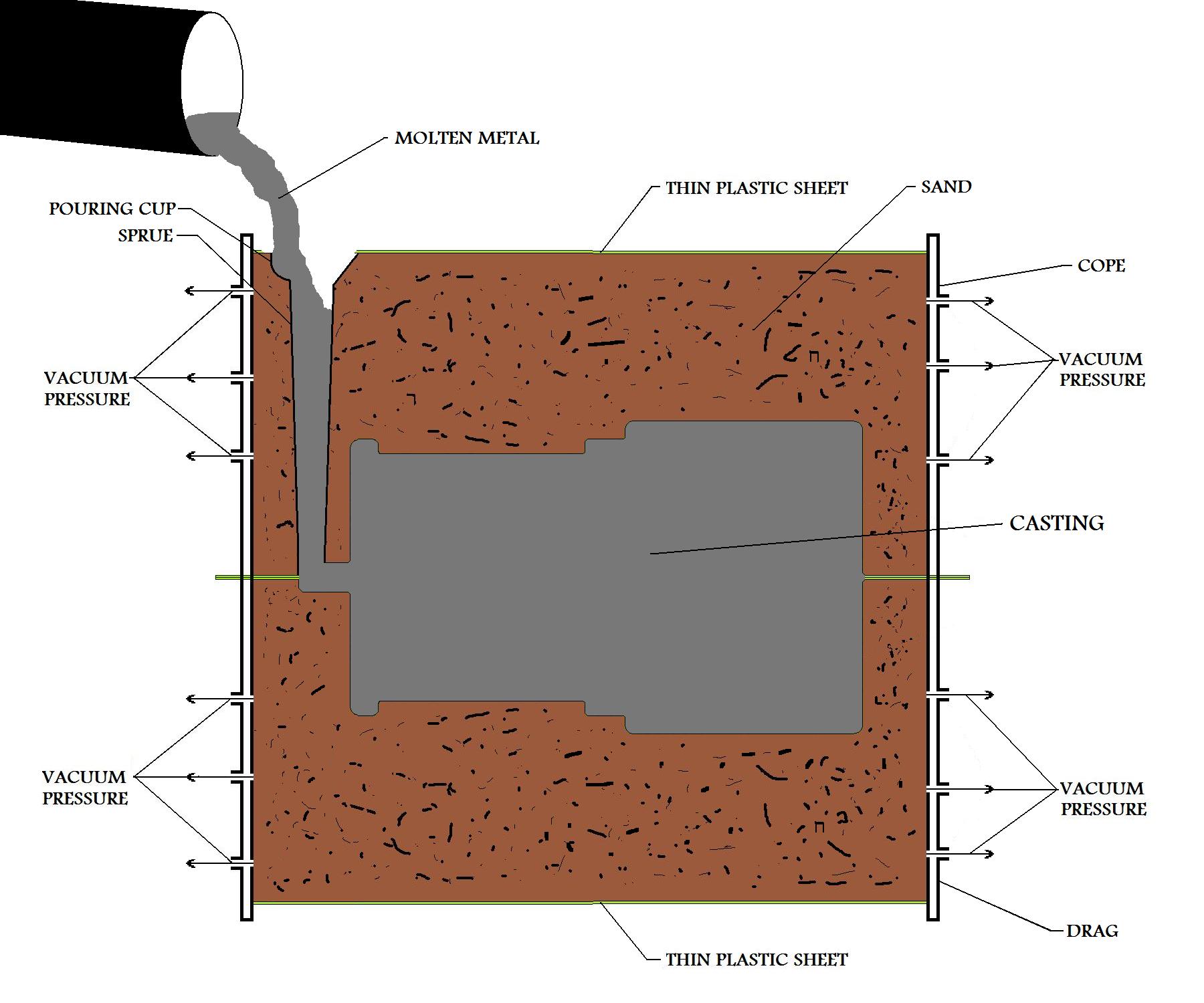

During the pouring of the casting, the molten metal easily burns away the plastic.

Figure:43

|

Properties And Considerations Of Manufacturing By Vacuum Mold Casting

- In vacuum mold casting manufacture there is no need for special molding sands or binders.

- Sand recovery and reconditioning, a common problem in metal casting industry, is very easy due to the lack of binders and other agents in the sand.

- When manufacturing parts by vacuum mold casting the sand mold contains no water, so moisture related metal casting defects are eliminated.

- The size of risers can be significantly reduced for this metal casting process, making it more efficient in the use of material.

- Casting manufacture by vacuum molding is a relatively slow process.

- Vacuum mold casting is not well suited to automation.