SHEET METAL FABRICATION Sheet Metal Manufacturing Sheet Metal Cutting Sheet Metal Bending Deep Drawing Sheet Metal Sheet Metal Ironing Sheet Metal Spinning High Energy Rate Forming Of Sheet Metal MANUFACTURING PROCESSES Metal Casting Metal Forming Metal Rolling Metal Forging Metal Extrusion Metal Drawing Powder Processes

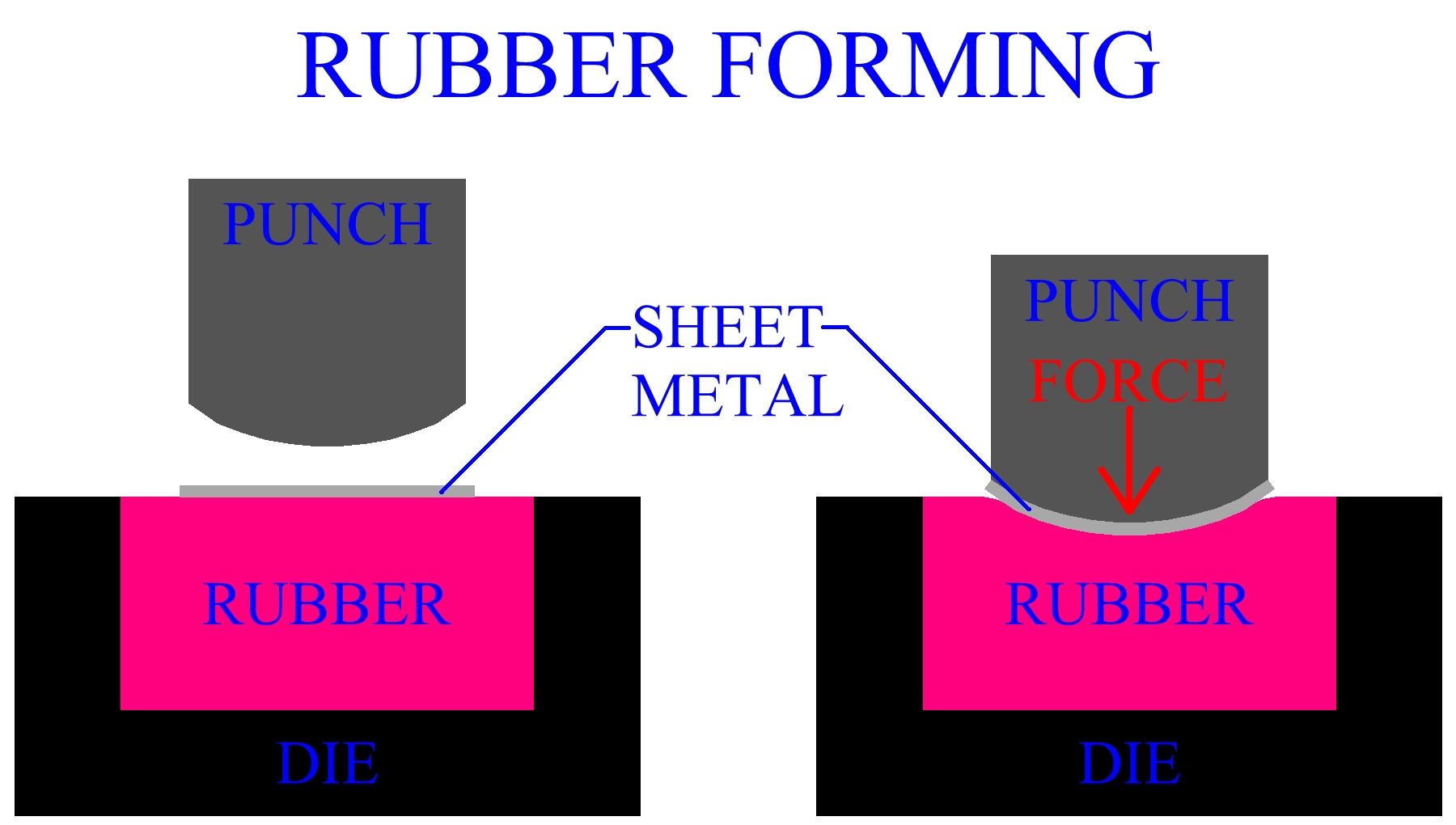

Rubber Forming

Rubber forming uses a flexible material, such as rubber or polyurethane, to form a sheet metal work piece. Often the rubber is incased in a steel container and serves as a punch. A work piece is placed over a rigid die. The punch forces the work into the rubber. Rubber is forced all around the work, creating pressure and forming the metal onto the die. This is known as the Guerin process. The location of the rubber can be switched between punch and die. In this case, a rigid punch presses a sheet metal work stock that is located over a die consisting of rubber incased in a steel container. The later process is illustrated below.

Rubber forming processes are limited in the depth of parts they can produce, (this is not true of hydroforming). Limitations in manufacturing exist because the pressure generated by the rubber is low, only 1500 lbs/in2, (10MPa). The same rubber punch or die can be used for many different forming blocks. Rubber forming is used in the aircraft industry to produce sheet metal components. Low cost tooling makes setup for rubber forming inexpensive. This manufacturing process is useful for the production of small quantities of parts.

Figure:314

|

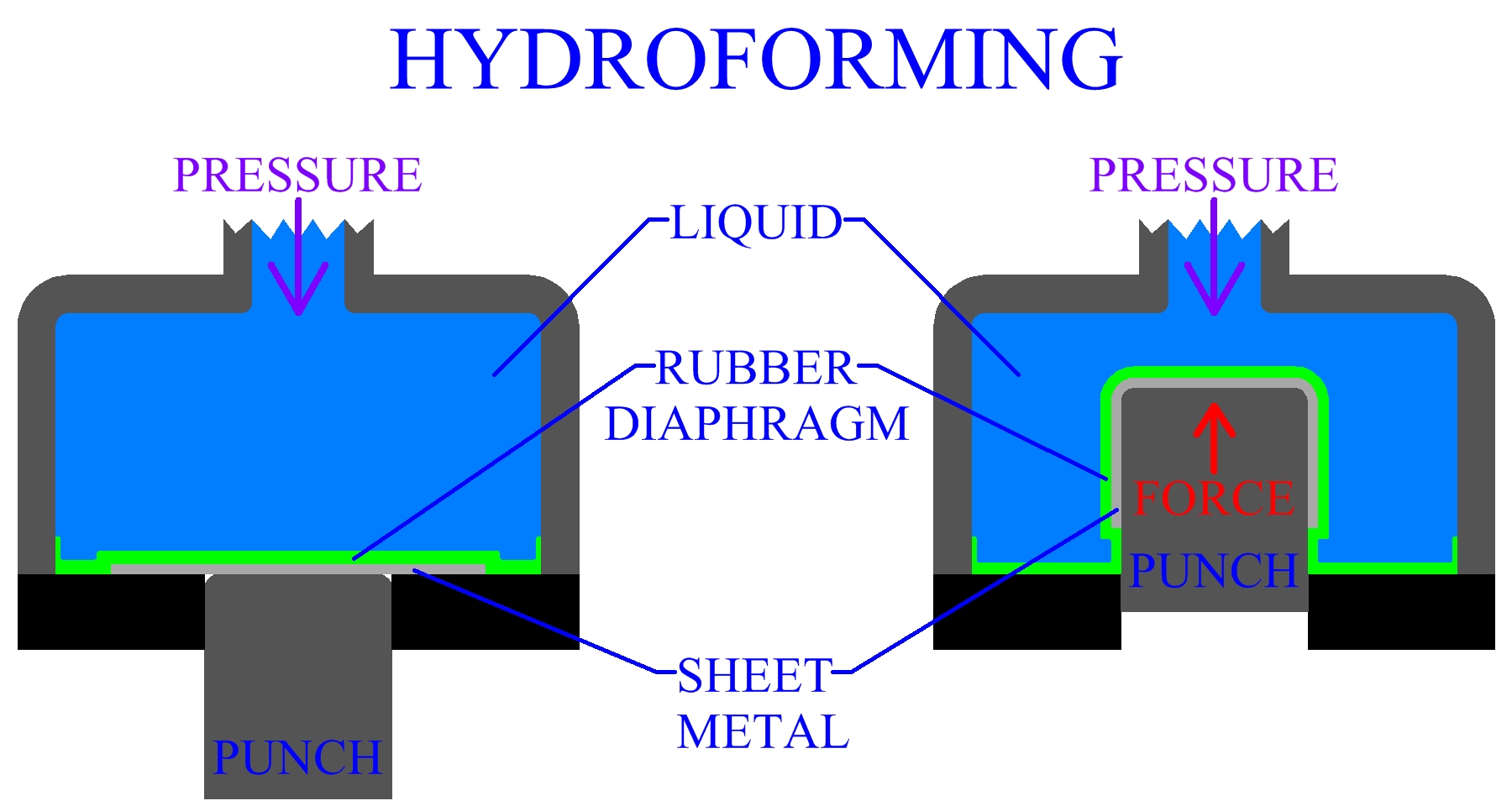

Hydroforming Of Sheet Metal

Hydroforming is an effective sheet metal forming process. Hydroforming can typically obtain deeper draws than conventional deep drawing operations. Hydroforming uses a rigid punch to push a sheet metal work piece into a rubber membrane. Behind the rubber membrane is a chamber of pressurized fluid. When the work is pressed into the chamber, the rubber membrane surrounds it completely and the pressure of the fluid forces the sheet metal to form on the punch.

Fluid pressure can be controlled during the operation and can be as high as 15,000 lbs/in2, (100MPa). Due to the large amount of evenly distributed pressure on the work piece, very deep draws, (high percent reduction), can be performed with hydroforming. Friction acts to reduce tensile stresses in the material during the process.

Lubrication affects friction and is an important factor in any type of rubber forming, (this includes hydroforming), process. One advantage of manufacturing by a rubber forming process is that the rubber, or flexible material, will be less likely to damage the surface of the sheet metal part.