EXTRUSION PROCESSES Metal Extrusion Extrusion Design Hydrostatic Extrusion MANUFACTURING PROCESSES Metal Casting Metal Forming Metal Rolling Metal Forging Metal Drawing Sheet Metal Powder Processes

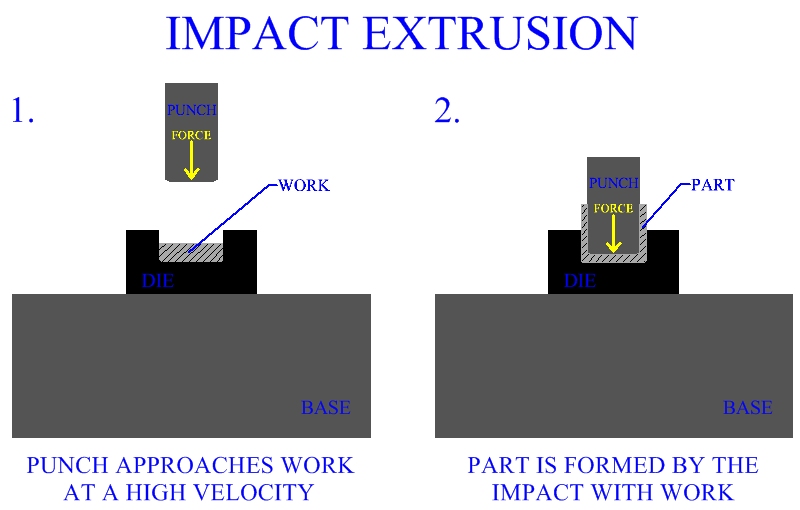

Impact Extrusion

Impact extrusion is a discrete manufacturing process, in which a metal part is extruded through the impact of a die with the work stock. The part is formed at a high speed and over a relatively short stroke. In standard metal extrusions, the force to extrude the work is commonly delivered by way of a hydraulic press. In impact extrusions, mechanical presses are most often employed. The force used to form standard extrusions is usually delivered over a horizontal vector, producing a long continuous product. Force used to form impact extrusions is usually delivered over a vertical vector, producing a single part with each impact of the punch. Impact extrusion is most often performed cold. Occasionally with some metals and thicker walled structures, the work is heated before impact forming it. This process is best suited for softer metals, aluminum is a great material for forming by impacting.

Figure:228

|

The Mechanics And Design Of Impact Extrusions

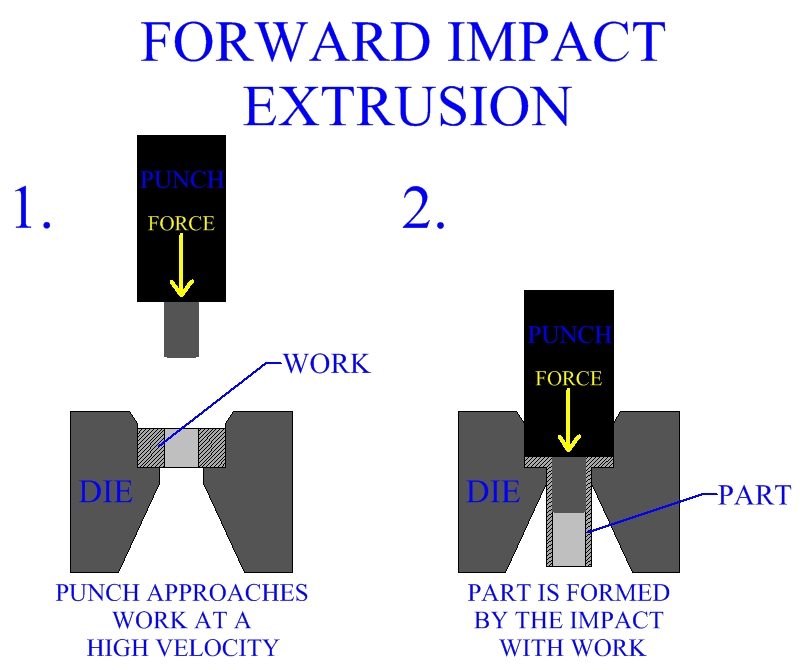

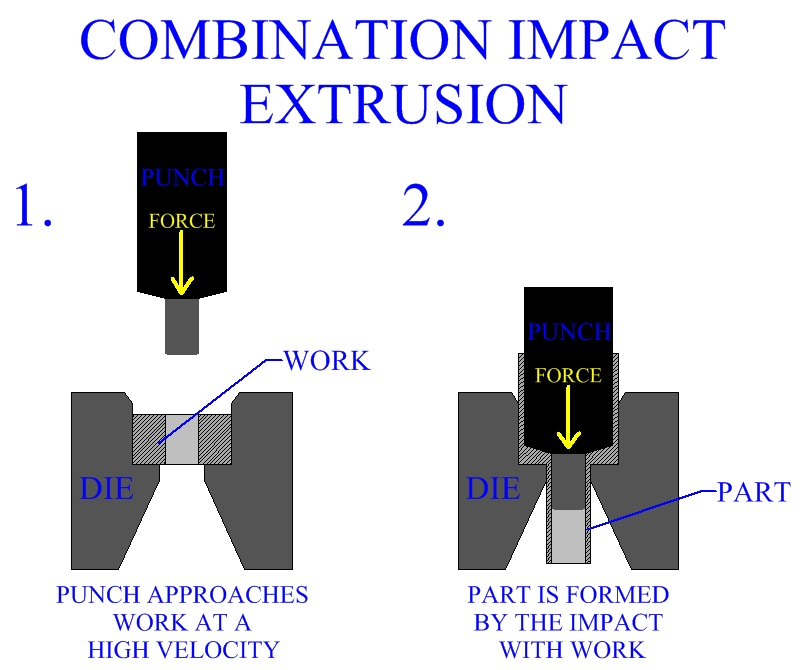

During the manufacturing operation of impact extrusion, a work piece is placed in a mold and struck with great force, causing the metal to flow into position in an instant. The forces acting on the machinery are extreme, particularly on the punch and die. Tooling must have sufficient impact resistance, fatigue resistance and strength, for extruding metal by impact. There are three basic types of impact extrusion processes, forward, reverse and combination. The different categories are based on the kind of metal flow that occurs during the process. In forward impact extrusion, metal flows in the same direction that the force is delivered. In backward impact extrusion, the metal flows in the opposite direction that the force is delivered. In combination, the metal flows in both directions. Backward extrusion is shown in figure 228, forward and combination impact extrusions are illustrated as follows.

Figure:229

|

Figure:230

|

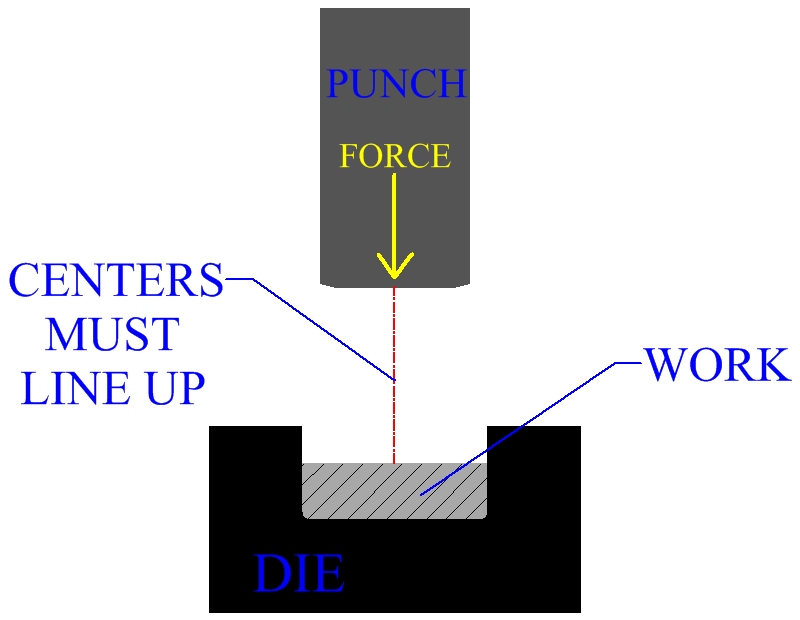

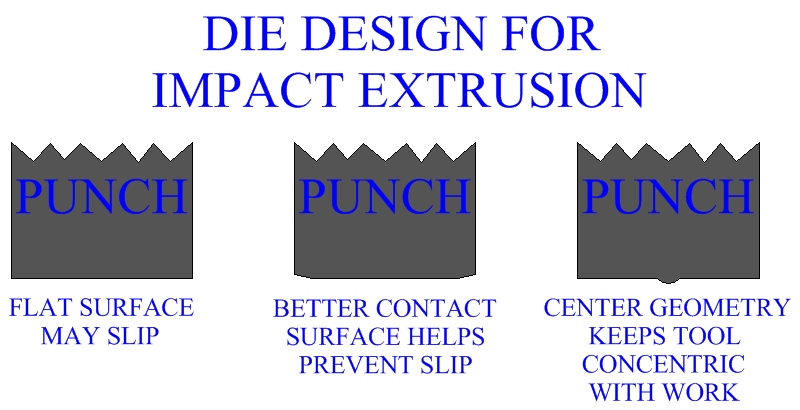

When designing an impact extrusion process, it is important that the part geometry be symmetrical about the punch. In addition, it is essential to the proper forming of the extruded component, that the punch die delivers a precise blow concentric to the work.

Figure:231

|

The end of the punch is better designed not to be completely flat, to avoid slipping at the punch-work interface. Sometimes a center point recess can help keep the punch concentric to the work.

Figure:232

|

Another factor, when manufacturing by this process, is the proportion between an impact extrusion's length and its internal diameter. Long punches with relatively small diameters may fail during manufacture.

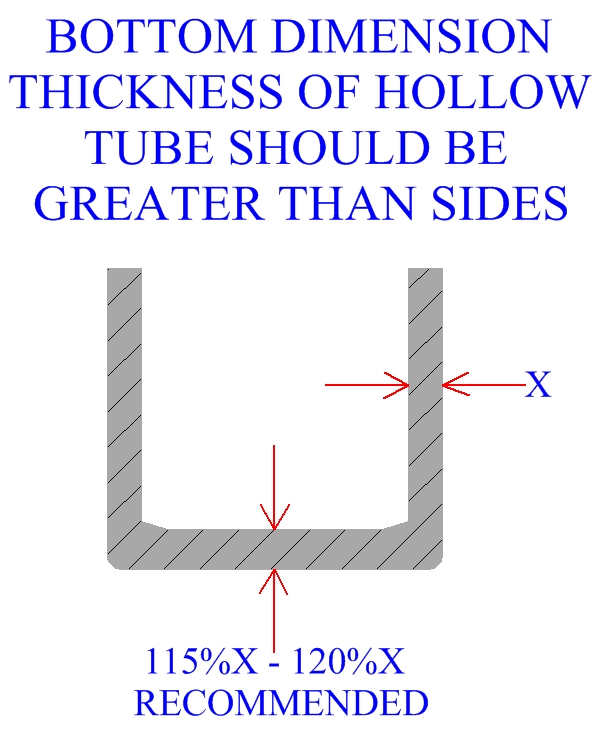

Hollow thin walled tubes, closed on one end, are often produced in manufacturing industry by backward impact extrusion. It is good practice to design the extrusion so that the bottom is at least 20% thicker than the sides, to help prevent metal breakage.

Figure:233

|

Impact Extrusion In Modern Manufacturing

Impact extrusion is used to manufacture a variety of parts, such as components for machinery and appliances. Impacted metal parts of complex geometries can be produced as long as the part is symmetrical over the axis by which it is formed. One of the best utilizations of this type of operation is in the production of hollow metal tubes with one end partially or completely closed. Hollow metal tubes may be extruded with internal and external geometry. The wall thickness of a part manufactured by impact extrusion may vary along its length, so may its interior and exterior diameters. Metal extrusions created by this manufacturing process do not need to have a circular cross section. Noncircular, but symmetrical, parts are also formed. The impact extrusion manufacturing process is very effective at forming flanges on tubular parts. Flanges with varying diameters and geometric attributes may be formed along the length of the extruded metal section. Bosses and hollow tubes, concentric to the extrusion axis, can be formed within hollow metal tubes by impact extrusion.

Many of the parts formed by impacting, in industry, will require further manufacturing processes, such as metal forging, ironing or machining, before completion. Impact extrusion can work harden a part, this may or may not be desirable. If necessary, a component may be annealed before further processing occurs. Favorable grain structures, good surface finish and high productivity are some possible advantages of manufacturing by impact extrusion.